- <Home>

- ForgeFix>

- Home & Hardware>

- Bolts & Nuts>

- <Washers>

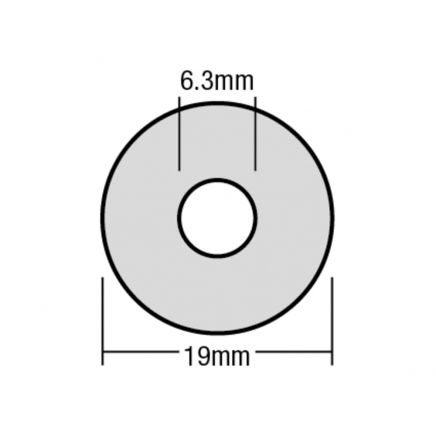

- Spring Washers, ZP

These Forgefix Spring Lock Washers ring-shaped, split at one point and bent into a helix. This shape means that the washer exerts a spring force between the fastener's head and the base item. The main purpose of the Spring Washer is to prevent loosening of the fastener by either movement or vibration.

These washers are bright zinc plated for increased corrosion resistance.

APPLICATION

Ideal for all manner of bolting applications where movement or vibration may cause loosening. Typical examples would be engineering and machinery.

Can be used with all types of bolts and nuts.

Zinc coatings prevent oxidation of the protected metal to create a longer lasting finish. It does this by forming a barrier and by acting as a sacrificial anode if this barrier is damaged. Zinc oxide is a fine white dust that (in contrast to iron oxide) does not trigger a breakdown of the substrate’s surface integrity as it is formed. The zinc oxide, if left intact, can act as a barrier to further oxidation, in a way similar to the protection afforded to aluminum and stainless steels by their oxide layers.

New content loaded

These Forgefix Spring Lock Washers ring-shaped, split at one point and bent into a helix. This shape means that the washer exerts a spring force between the fastener's head and the base item. The main purpose of the Spring Washer is to prevent loosening of the fastener by either movement or vibration.

These washers are bright zinc plated for increased corrosion resistance.

APPLICATION

Ideal for all manner of bolting applications where movement or vibration may cause loosening. Typical examples would be engineering and machinery.

Can be used with all types of bolts and nuts.

Zinc coatings prevent oxidation of the protected metal to create a longer lasting finish. It does this by forming a barrier and by acting as a sacrificial anode if this barrier is damaged. Zinc oxide is a fine white dust that (in contrast to iron oxide) does not trigger a breakdown of the substrate’s surface integrity as it is formed. The zinc oxide, if left intact, can act as a barrier to further oxidation, in a way similar to the protection afforded to aluminum and stainless steels by their oxide layers.

Delivery Information